|

|

| |

|

|

|

...:::... ...:::... |

|

|

|

|

|

|

|

WHAT IS CLASSIFIED PERLITE?

CLASSIFIED PERLITE is to be sized by passing through

different spaced fine sieves after raw perlite is broken

in gaps, which are 0,0 - 0,25mm. Production can

be done in dimensions below and besides in wanted grain

dimensions.

Production can be done in 0 -0.6 mm. , 0.6-1.2 mm. ,

0.6-2.5 mm. , 1.2-2.5 mm. grain dimensions.

USING PLACES OF CLASSIFIED PERLITE

At

melted of mines time, it is used to provide coming

into being dross by being thrown inside furnace and to

be constituted dross under control.

It is put to sole of crucible before being taken

to crucible from furnace of metal in casting industry.

If when perlite get in touch with hot metal, it does a

sort boiling and provides to be taken more clean

casting by carrying to crucible surface of emprutels

which can be found in metal.

At carried of metal into crucible that, it is used

to hindering to surface cooling in casting industry

again.

At casting that being put a quantity to sole of

crucible, is used to prevent cooling from crucible

surface before casting to moulds with better cleaning

of metal. With these intentions, Classified Perlite

has been using in 1180-1300 kg/m3 density and in

0.6-1, 1 -2 mm. grain dimensions.

It is used in

production of expanded perlite.

PROPERTIES OF CLASSIFIED PERLITE

Physical Chemical

Density(kg/m3) 1000-1300 Sİ02 %71-75

Expanding heat(°C) 800-1150 AI2O3 %12-16

Free moisture(%) 0.5 max. Na2O %2.9-4

pH 6.6-8 K2O %4-5

H2O %3.05-5.16

PROPERTIES OF ETIPER

Physical Chemical

Colour White SİO2 %71-75

Melting Dot 1300°C AI2O3 %12-16

Heat Conductivity 0,034-0,045 Na2O %2.9-4

Kcal/Mh°C

Density 32 - 200 Kg/m3 K2O %4-5

CaO %0,2-0,5

ETIPER PRODUCTIONS (Etiper "Normal)

Dimensions 0,0 -2,5 mm

Density 60-80 Kg/m3

Heat Conductivity 0.034 - 0.045 Kcal/mh'C

Packing in polyethylene which is 200 dm3

or in polyprophylene sacks.

Etiper "Super fine" (Criogenic Perlite)

Grain Dimesions 0.0-1.2 mm.

Slack density 40-50 Kg/m3

Density which had been tightened 55-75 kg/m3

Heat Conductivity 0.034 - 0.045 Kcal/mh'C

Packing in polyethylene sacks

which is 200 dm3.

|

|

|

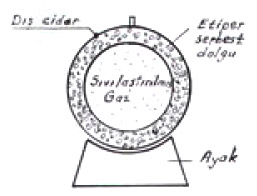

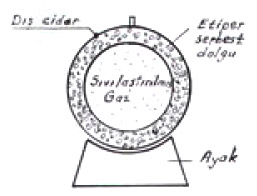

a) In HEAT INSULATION of Criogenic Tanks

Protection on liquefying heat in pair side

tanks of all gases, which had been liquefied in low

heats (up to -270 °C}, has been being possible with

Etiper "Super fine" which heat conductivity value is

very low. It isn't humudity, doesn't spoil, doesn't burn

and this material, which is cheap, is freely filled

between pair side of tank in atmosphere pressure or

under vacuum. |

|

| |

|

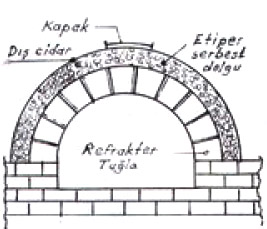

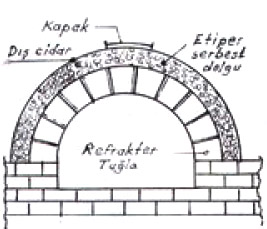

b) In HEAT INSULATION of different furnaces and of

systems

Etiper "Super fine" has been using to

prevent heat shopping (heat lost) with outside

environment in furnaces which is working environment

up to maximum + 1050 °C. Free filling is done to outside

surface of furnace (between pair side).

|

|

| |

c) In Production Of Refrakter Brick

Etiper "Normal" is used as

contribution substance in production of used bricks in

Cauldron, furnace, dampening-beating, thermal operation

and melting stoves which are its working environment up

to maximum + 1050 °C.

Produced refrakter blocks and bricks result of being

tied with clay or calcium silicate cement of Etiper

"Normal" provide high propotion insulation besides being

light. Consequently they do fuel saving.

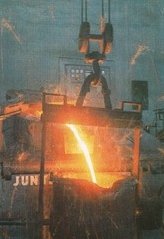

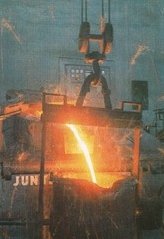

d) In casting industry

Etiper "Normal" is used as

contribution substance to casting sand. It is added

volumely %8-12 proportion to casting sand in casting of

iron-steel, % 20-30 proportion as for in casting of

other materials.

ADVANTAGES, WHICH WILL PROVIDE, OF ETIPER "NORMAL"

IN FOUNDRY

- It prevents abnormal surface tensions because of

providing slowly and balanced cooling of metal.

- At casting time, it doesn't Burn, doesn't take off

Gas and doesn't enter to Reaction with Metal.

- It gives permission to exit by means of

emptinesses and canals which are in Building of gases,

which is constituted at casting time.

- Clean, strong, high in quality and productive

casting are got.

- It lessens workmanship and cleaned time of

production becausae of taking down casting errors to

minimum.

|

| |

| |

|

...:::...

What Is Perlite ?

...:::... |

| |

|

Why need

to be used? |

|

In the roofs |

|

On the walls |

|

In agriculture |

|

In filtering |

|

In industry |

| |

| |

| |

| |

|

|

|

|

|