|

WHERE ARE THEY USED?

Wallmate TB is a thermal bridge resistance material

developed by Dow as the result of its 50 years'

technical expertise and remains unchallenged until

today.

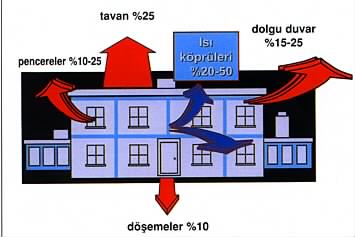

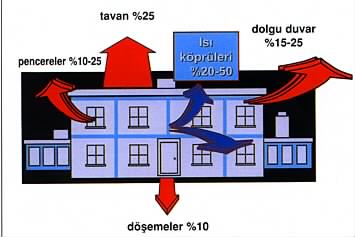

Wallmate TB as a wall thermal resistance material is a

product developed for the external insulation of the

building elements like columns, beams, flanks, lento

etc. that are described as thermal bridges for the

applications where thermal resistance boards are built

as internal walls or sandwich walls.

For the applications where thermal resistance boards are

built as internal walls or sandwich walls as the result

of the Wallmate TB boards and the thermal bridges being

insulated from outside a healthy thermal insulation

close to ideal situation would have been obtained.

HOW ARE THEY APPLIED?

1- The assembly of the boards.

Wallmate TB boards are placed by being put into the

mould before the cement is formed as well as by being

fixed to the external faces of the carrier elements like

columns, beams etc. after the cement has been formed.

A) Placement into the mould.

1- Appropriate to the sizes of the columns, beams, and

flanks or lento the preparation of the Wallmate TB

boards in conformity of the measurements made using the

qualities in line with easy brake technique by way of

breakage.

2- The placement of the Wallmate Tb boards by way of

eliminating any gaps in-between the molding wood for the

process of placement of the Wallmate TB boards into the

mould itself broken accordingly to the sizes measured

previously.

3- The separation of the iron rigger from the Wallmate

TB boards so that a rust gap is left in between.

The Wallmate TB boards help the cement to cover the rigs

appropriately during the preparation of the cement due

to its high mechanical resistance. Because it doesn't

absorb water into its body the values relating to lambda

do not deteriorate. In addition, especially during the

summer times prevent the cement loosing excessive water

and help a healthy path of winding to happen.

In order for the boards to be attached to the cement

block the surfaces of the boards have specially

developed grooves and rugged faces. Using this method

the process of unfolding will happen more efficiently

and when the mould is taken out the Wallmate TB boards

will have been obtained in a position attached to the

cement block. Materials of walls like bricks, Bims block

and Gazbeton can be aligned with the external surfaces

of the Wallmate TB boards and thus thermal resistance

application to theses parts can be achieved from inside

or sandwich wall production can be facilitated.

B) THE FIXATION PROCESS TO THE

HEADS OF COLUMNS AND BEAMS OF THE AFTERMATH

1- Appropriate to the sizes of the columns, beams, and

flanks or lento the preparation of the Wallmate TB

boards in conformity of the measurements made using the

qualities in line with easy brake technique by way of

breakage.

2- It must be fixed to the cement faces with plastic

nailed insulation dabbles, close to walls and the

corners of columns-beams or in crossed spaces of 50 cm.

And the dabbles are to be inserted into the cement by at

least 5 cm. In the case of the concrete block bulges

arising from mould failures on the surfaces where the

process is being applied, and these failures prevent the

placement of the boards to the surfaces, the surface

must be broken to be corrected or must be corrected

using alum.

3- In the case of the process of

fixation taking place before the building up of the

wall, the external faces of the bricks, blocks of bims

and gazbeton must be aligned with the external faces of

Wallmate TB boards.

4- In the case of blocks of wall set up previously, it

must be build over to the outside at 3-4 cm. Distance

from the surfaces of the columns-beams (according to the

thickness of the Wallmate TB boards).

2- The Process of Plastering

Before the process of application of plastering to the

surfaces of Wallmate TB boards is started care must be

given that the re are gaps left between the boards. If

there are any these gaps must be filled with Wallmate TB

boards rather than with mortar. If a long time has

passed before the application of plastering has started

and the boards of Wallmate TB have been subjected to UV

rays for a long time, a change of coloring and dusting

might occur on the surface. In this case, the dust must

be removed from the surface using a brush. To prevent

this from happening during the pouring of the cement and

the process of plastering, and a long period is planned

to be left in-between the Wallmate TB boards are to be

protected by light colored covers from the effects of

the UV rays or during the setting up of the wall, must

be fixed to the columns and beams and then are to be

plastered.

The application of plastering can be carried out using

rigger filet or galvanized rabitz wire.

A) In the case of the rigger filet being used:

1- First a single layer of plaster is put onto the

Wallmate TB surface where application of filet is to be

carried out.

2- While the plaster is still wet the rigger filet is

attached to the plaster surface-using trowel. Depending

on the ambient temperature after a period of waiting for

2-24 hours for the path of winding to take effect, the

whole front is to be plastered thin and thick. To

prevent cracks due to work on the building, the

differences in temperature changes etc., only at the

points of enclosures and 20 cm. above the surfaces of

the walls a plaster rigger filet must be used. The filet

must be laid on top of each other reaching 10 cm on top.

The filet to be used for this application must be

alkaline proof, at 130-gr/m2 weight (12 mm x 12 mm filet

porosity) and more importantly must have in two

directions at least 1500 N/5 break resistance. Higher

break resistance values facilitate better security

levels.

B) In the case of galvanized plaster wire to be used.

In the case of the frontal surface faults requiring a

traditional type of plaster to be used, we recommend

that galvanized plaster wires be to be used.

1- It is fixed running over the edges of the

face of the walls about 20 cms to the surfaces where

galvanized plaster wire Wallmate TB is directly applied.

It is to be put on top of each other at 10 cm intervals

at the galvanized plaster wire attachments.

2- Then plaster is applied thin and thick.

In the case of the application of Wallmate TB for the

present buildings at a later stage, it is advised that

to check the surface if it is appropriate for the

pasting to be applied.

ADVANTAGES

- Even the water is placed into the mould due to

its water absorption capacity does not affect it.

- Due to its high mechanical

resistance the concrete vibration in the mould does not

affect it.

- It provides capability to break

every 5 cm without the need to use model set knife.

- Due to its grooved and

specifically designed rugged surface it attaches to the

concrete surfaces as well as with the use of traditional

plaster types.

TECHNICAL

SPECIFICATIONS FOR THE INSULATION MATERIALS OF WALLMATE

TB THERMAL BRIDGES

MATERIALS FOR THERMAL RESISTANCE (TS 11989

compatible):The cap less porous polystyrene - extruded

foam XPS boards used for the application of insulation

of thermal bridges must be easily breakable in multiples

of 5 cm layers and thus in form of boards to be fixed to

the carrier system without the need to use model set

knifes. Its surfaces must definitely be rugged and more

importantly have wide grooves, which allow pasting to

concrete and with the use of traditional type of

plasters (TSE 825 standards, article number 10.2.1.2.1.

of attachment number 5 of the official gazette numbered

and dated 23725 and June 14, 1999). In the case of

surfaces not having wide grooves not being rugged the

paste resistance of the boards between the concrete and

the traditional plaster shall not be sufficient.

RATE

OF THERMAL CONDUCTIVITY (LAMDA). It must not be

larger than 0.030 W/m.K for aging at 10 C for 90 days.

DENSITY. Must not be at lower than 28 kg/m3 density.

Although under TS 825, article number 10.2.1.2.1 of

attachment number 5 the lower limit of density is given

as 20 kg/m3 for the boards with rugged surfaces it is

necessary to produce them at values of 28-30 kg/m3

densities to be used to be able to obtain the value of

0.030 W/m.K.

SIZE

DETERMINATION:

a) Change of dimensions in the length and the

width must be zero at 60 C and 90 % relative humidity.

b) Change in dimensions must not exceed 2 % under

20-kPa stresses and at a temperature of 80 C.

c) Must not exceed 2 % under 40-kPa stresses and

at a temperature of 70 C.

Size determination is one of the most important factors

especially for the wall applications of thermal bridges.

Size changes occurring due to differences in

temperatures might create problems on the frontal

surfaces. The sizes of the cells, their placements and

their balances in three directions are very important

regarding paste resistance and size dimension involved.

WATER

ABSORBTION: The water absorption rate for prolonged

periods using full dipping method must not exceed 0.5 %

in volume. Otherwise, the thermal resistance material

absorbs the water of the concrete it is in contact with

or the water of the traditional plaster it is in contact

with and changes the rate of thermal conductivity

(lambda) and the building will start to consume more

energy than anticipated at the beginning.

THE

PASTING RESISTANCE TO THE CONCRETE: The pasting

resistance of the thermal resistance boards to the

concrete must not be lower than 300 kPa in the case of

the thermal resistance boards being put into the moulds

before the cement is poured.

THE

PASTING RESISTANCE WITH THE TRADITIONAL PLASTER TYPES:

The pasting resistance of the thermal resistance boards

with the traditional plasters must not be lower than 150

kPa.

WATER

VAPOUR DIFFUSION RESISTANCE. It must bein between 90

and 110. The values must remain at these levels so that

no condensation occurs at the column and beam cross

sections and at the same time the building can take

wind.

PRESSURE RESISTANCE. Must not be lower than 200 kPa

(TSE 11989, class C2).

RESISTANCE TO FIRE. Must pass the B2 test first,

then must be proven that it has passed B1 class by

applying furnace tests and that it has not been

dripping. Besides the documents obtained from TSE there

must also be certificates granted by the test institutes

in Germany.

CAPILARITY. Must be zero.

SPECIFICATIONS OF THE SURFACE AND CAPACITY FOR BREAK AND

PASTE: must be easily breakable in multiples of 5 cm

layers and thus in form of boards to be fixed to the

carrier system without the need to use model set knifes.

Its surfaces must definitely be rugged and more

importantly have wide grooves, which allow pasting to

concrete and with the use of traditional type of

plasters

LENGTH, WIDTH, DEVIATION FROM THE SET SQUARE, SURFACE

PLANE, THICKNESS. Must be in conformity of the

tolerance levels stated under the standards of TS 11989.

SIDE

PROFILES: the fact that the corners are flat is

useful for repeated usage of the broken pieces and to

speed up the application process.

* Trademark of Dow

Chemical Company. |