|

WHERE ARE THEY USED?

SHAPEMATE* IB is used on the outisde surfaces of walls

by bounding and dabbling. The boards are produced with

rugged front surfaces to increase the paste power for

applications from outside. On the back surfaces along

its height it is grooved at 5 cm intervals with a size

of 5x5 mm. To enable perfect pasting.

HOW ARE THEY APPLIED?

- For the

external insulation, the boards are pasted to the

external face of the wall using cement based pastry

mortar without solvent content. (If on the back face

there is some kind of painting etc. that is preventing

ease of pasting, the surface is to be abrades and thus

prepared for pasting).

- The pastry

mortar is left drying for a while and the boards are

fixed to the surface at the back in rows of 6 for every

m2 using plastic nail insulation dabbles. (The dabbling

process is very important and if the back face is not

right for the process a rough plastering of 2 cm.

Thickness is to be provided).

- Cement based

plaster with added latex is applied directly onto the

surface of the boards in thickness of a few mms. Alkali

proof glass fleece plaster rigger filet is pasted onto

the plaster surface (before it is dried) using steel

trowel. And later a few mm. Of plaster is applied and

then left for drying. The most important matter in this

process is that the plaster rigger fillet is placed in

the middle of total external plaster layer or close to

its external face.

- Putting a

final layer of cover, which is decorative without any

solvent content and has a surface layer, which is rugged

but windy, completes the application process.

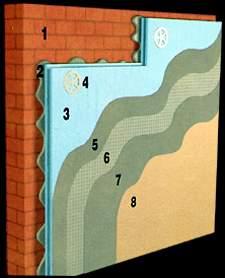

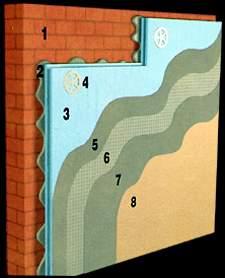

1)

External side of the walls

2) Adhesive mortar

3) Shapemate* IB thermal

resistance board

4) Dabble

5) Plaster (min. 2 mm.)

6) Fibermesh

7) Pasting plaster (min. 2

mm.)

8) Plaster |

ADVANTAGES

-

Shapemate IB thermal resistance boards can be used for

the roof of cellars, bottoms of porch balconies etc, and

for both columns and beams by putting into moulds as

well as by applying plasters later and eliminates heat

bridges due to its high thermal resistance capacity.

-

The rugged surfaces of the boards tightly grab the

surface where it is pasted to and also the plaster it is

pasted to remains strong for the length of life of the

building and keeps its thermal resistance qualities.

-

External insulation protects the external shell of the

building against differences in temperatures and thus

against wear.

-

Applications for external insulation prevent dampness by

allowing condensation to occur on the external face of

the building and establish a healthy living quarter.

-

Applications external insulation eliminates the change

of air movement due to the temperature of the wall

internal surface being close to ambient temperature and

fixed at the ambient temperature. Also prevents erosion

of the surface layer, split of the paint and plaster.

-

Shapemate IB thermal resistance boards do not require

renewal work to be carried out very often and keep their

thermal resistance characteristics for the length of the

life of the building.

-

Allows smaller and more economical use of devices for

heating and cooling. Economizes on maintenance and

operational work.

TECHNICAL

SPECIFICATIONS FOR THE MATERIALS OF SHAPEMATE IB FOR

EXTERNAL WALL INSULATION

MATERIALS FOR THERMAL

RESISTANCE (TS 11989 compatible TSE standards). For

the application external wall insulation cap less porous

polystyrene - extruded foam XPS boards used must

definitely have rugged and/or grooved surfaces (TSE 825

standards, article number 10.2.1.2.1. of attachment

number 5 of the official gazette numbered and dated

23725 and June 14, 1999). In the case of surfaces being

armored the paste resistance of the boards between paste

mortar and plaster shall not be sufficient. (For this

reason for the products having grooved and rugged

surfaces test results carried out according to TS 11989

by TSE must be obtained from the manufacturers).

RATE OF THERMAL

CONDUCTIVITY (LAMDA). It must not be larger than

0.031 W/m.K for aging at 10 C for 90 days. (For boards

with both of the surfaces being rugged test results

carried out at the laboratories of TSE must definitely

be obtained from the manufacturer).

DENSITY. Must not

be at lower than 25 kg/m3 density. Although under TS

825, article number 10.2.1.2.1 of attachment number 5

the lower limit of density is given as 20 kg/m3 for the

boards with rugged surfaces we propose values of 27-28

kg/m3 density to be used to be able to reach the value

of 0.031 W/m.K.

SIZE DETERMINATION

a) Change of dimensions in the length and the width must

be zero at 60 C and 90 % relative humidity.

b) Change in dimensions must not exceed 2 % under 20-kPa

stresses and at a temperature of 80 C.

c) Must not exceed 2 % under 40-kPa stresses and at a

temperature of 70 C.

Size determination is one of the most important factors

especially for the wall applications. Size changes

occurring due to differences in temperatures might

create problems on the frontal surfaces. The sizes of

the cells, their placements and their balances in three

directions are very important regarding paste resistance

and size dimension involved.

WATER ABSORBTION.

The water absorption rate for prolonged periods using

full dipping method must not exceed 0.5 % in volume.

Otherwise, the thermal resistance material absorbs the

water of the paste mortar or pasting plaster it is in

contact with and changes the rate of thermal

conductivity (lambda) and the building will start to

consume more energy than anticipated at the beginning.

In addition, as the result of freeze thaw circle of the

absorbed water cracks might occur in the plaster.

THE PASTING RESISTANCE

TO THE PLASTER. The pasting resistance of the

thermal resistance boards to paste plaster must not be

lower than 80 kPa. The preferred rates are larger than

100 kPa.

WATER VAPOUR DIFFUSION

RESISTANCE. It must be between 90 and 110. The

values must remain at these levels so that no

condensation occurs at the wall cross-sections and at

the same time the building can take wind. However, a

test for condensation at the wall cross sections must be

carried out under any circumstances (please refer to TS

825 standards given in the official gazette numbered and

dated 23725 and June 14, 1999).

PRESSURE RESISTANCE.

Must not be lower than 200 kPa (TSE 11989, class C2).

RESISTANCE TO FIRE.

Must pass the B2 test first, then must be proven that it

has passed B1 class by applying furnace tests and that

it has not been dripping. Besides the documents obtained

from TSE there must also be certificates granted by the

test institutes in Germany.

CAPILARITY. Must

be zero.

SPECIFICATIONS OF THE

SURFACE. For the application of thin layer pasting,

the external surfaces where plaster is applied must only

be rugged (not grooved), the back face pasted to the

wall must be rugged as well as grooved. Thus, better

pasting to the back face shall have been obtained and a

relatively more homogenate plaster surface would have

been obtained on the external side.

LENGTH, WIDTH,

DEVIATION FROM THE SET SQUARE, SURFACE PLANE, THICKNESS.

Must be in conformity of TS 11989.

SIDE PROFILES. The

long sides being tongued would prevent the work of heat

bridges.

* Trademark of Dow

Chemical Company.

|