|

WHERE ARE THEY USED?

Roofmate* SL is the ideal thermal insulation material of

the flat roofs thermal resistance roofs which is

suitable for walking on or not or greenhouse type flat

roofs.

HOW ARE THEY APPLIED?

- After the

application of the slope cement, the drainer and water

proof membrane, both water impermeability and drainage

tests have to be carried out.

- The Roofmate

SL boards are placed freely on the water proof membrane

system. Care must be given to put the sides of the

boards on top of each other, in full line and that the

boards do not fly off in stormy weather conditions.

- A filter

layer (felted cloth, geotextile) is laid out on the

boards and materials like sand etc. Are thus prevented

from flowing down the water and board joints.

- Gravel of 5

cm. Thickness (Æ16-32 mm.) is

laid on the flat roofs, which is not suitable for

walking on. On the flat roofs where people can walk on

thin layer of gravel is laid on top of the filter layer.

The boards are laid on this gravel without using mortar

and the detailed work is then completed. Or, without

using a filter layer and gravel the boards are placed on

top of the Roofmate SL boards with the use of plastic

filler blocks. Both of the details allow ease of use for

maintenance purposes.

- It is

possible to fix the boards on the felted cloth and on

the layer of thin (Æ 4-8 mm.)

gravel of 2-3 cm. Thickness and to use covers like

mosaic or alum. However, it is preferred that the cover

layer allows the flow of vapor.

- For

greenhouse roofs a repeated filter layer and vegetation

earth is laid on top of the gravel layer.

- The drainers

to be used must be set to draw any water from all layers

and their numbers and capacity must be able to drain

water at a fast speed.

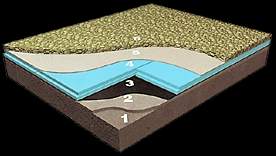

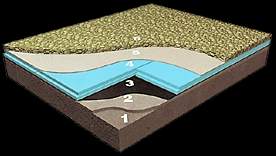

1) Floor cement

2) Slope cement

3) Water proofing membrane

4) Roofmate * SL thermal

insulation board

5) Separator layer (felted cloth,

geotextile etc.)

6) Gravel (Æ

16-32 mm., min. 5 cm.)

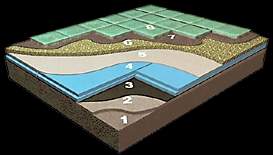

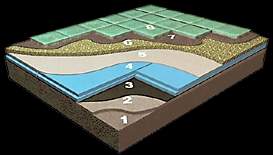

1) Floor cement

2) Slope cement

3) Water proofing membrane

4) Roofmate * SL thermal

insulation board

5) Separator layer (felted cloth,

geotextile etc.)

6) Gravel (Æ

4-7 mm., min. 2 cm.)

7) Mortar

8) Board covering

ADVANTAGES

- At the traditional application of flat roofing

systems the thermal insulation material is protected

from water by using water insulation at top and bottom

barriers. However, in this situation the water proof

membrane are quickly worn out due to the differences in

temperatures and the effects of mechanical influences,

thus loosing its thermal insulation specifics and

requires very expensive maintenance and renewal work. In

addition, it requires very high quality materials and

workmanship and it is not compatible with the physical

specifications of the building itself.

- For the inverted roofing system

the water proofing membrane are protected from effects

mentioned above with the help of Roofmate SL boards.

Also, it doesn't require use of vapor barriers and

protection cement, with less cost, its application is

simple and fast, can be applied under every weather

condition.

- It can

be uninstalled easily to check on the status of water

proof membrane; after maintenance work is carried out it

can be reinstalled without any loss of material and

quality. Hence, costs related to maintenance and repair

is kept at lowest levels.

- The Roofmate SL boards have a

minimum pressure resistance of 30 tons/m2 and stretch

resistance of 2 %.

- The boards are snow and frost

proof, is highly resistant to frost-thaw circle.

TECHNICAL SPECIFICATIONS FOR THE MATERIALS OF ROOFMATE

SL FLAT ROOFING SOLUTIONS

MATERIALS FOR THERMAL RESISTANCE (TS 11989

compatible TSE standards). For the application of

terrace roofing systems the cap less porous polystyrene

- extruded foam XPS boards used must definitely have

armored (binded) surfaces (TSE 825 standards, article

number 10.2.1.2.2. of attachment number 5 of the

official gazette numbered and dated 23725 and June 14,

1999). In the case of surfaces being curse the use of

the boards on the reversed roofing systems is not

appropriate regarding the values of thermal conductivity

(lambda), water absorption, frost thawing.

RATE

OF THERMAL CONDUCTIVITY (LAMDA). It must not be

larger than 0.027 W/m.K. After aging at 10 C for 90

days.

DENSITY. Must not be at lower than 32 kg/m3 density.

Although under TS 825, article number 10.2.1.2.2 of

attachment number 5 the lower limit of density is given

as 30 kg/m3 for the boards with armored (binding)

surfaces we propose values of 32 kg/m3 and higher to be

used.

PRESSURE RESISTANCE. Must not be lower than 300 kPa

(TSE 11989, class C3).

STRECH

RESISTANCE. It must not be lower than 110 kPa. (This

value can be defined as the load at its maximum, which

the material can carry for 50 years on a continuous

basis under a deformation of up to 2 %. Also, as the

load for statistical calculations 110 kPa should be

taken as basis instead of 300 kPa).

WATER ABSORBTION. The water absorption rate for

prolonged periods using full dipping method must not

exceed 0.2 % in volume.

WATER

ABSORBTION WITH DIFFUSION OVER LONG PERIODS. The

rate of water absorption with diffusion over long

periods must not exceed 1 % in volume.

FROST

THAW. The rate of water absorption using freeze thaw

method must not exceed 0.2 % in volume. Also, the

reduction in pressure resistance as the result of freeze

thaw test must not exceed 2 % (the rate of 10 % as the

standard is the upper limit).

WATER

VAPOUR DIFFUSION RESISTANCE. It must be between 100

and 200.

SIZE

DETERMINATION

a) Change of dimensions in the length and the width must

be zero at 60 C and 90 % relative humidity.

b) Change in dimensions must not exceed 2 % under 20-kPa

stresses and at a temperature of 80 C.

c) Must not exceed 2 % under 40-kPa stresses and at a

temperature of 70 C.

RESISTANCE TO FIRE. Must pass the B2 test first,

then must be proven that it has passed B1 class by

applying chimney furnace tests and that it has not been

dripping. Besides the documents obtained from TSE there

must also be certificates granted by the test institutes

in Germany.

CAPILARITY. Must be zero.

SPECIFICATIONS OF THE SURFACE. Must be armored

(binding).

LENGTH, WIDTH, DEVIATION FROM THE SET SQUARE, SURFACE

PLAIN, THICKNESS. Must be in conformity of TS 11989.

SIDE

PROFILES. Tongue grooved side profiles would prevent

the work of heat bridges.

STRETCH RESISTANCE. Must not be lower than 110 kPa

at the applications on the beam rafter without roof

wood. Otherwise, people would not be able to walk on it.

Even at these values the thickness of the board and the

gaps left between beams rafters must not exceed the

values given by the manufacturers.

* Trademark of Dow

Chemical Company.

|