|

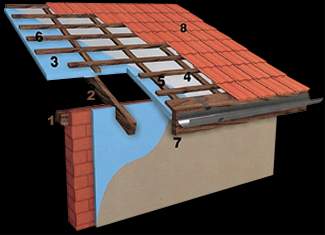

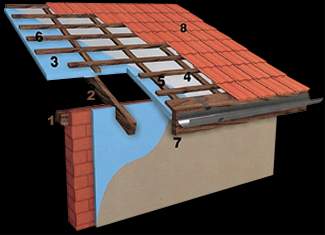

ROOFMATE PS For Pitched Roofs

WHERE ARE THEY USED?

Roofmate PS Boards * are applied on pitched roof,

without using any roof wood and together with the

thermal insulation applied on the beam rafter (Covered

Insulation System), all kinds of tiles and roof cover.

HOW ARE THEY APPLIED?

- The cross

sections of the beam rafters and joints are calculated

having taken into account the materials used on the

roofs and their weight and the beam rafters are placed

in intervals of 40 cm, If Roofmate PS of 4 cm thickness

are to be used, 50 cm of intervals if Roofmate PS of 5

cm thickness is to be used, and 60 cm of intervals if

Roofmate PS of 6 cm thickness is to be used.

- Roofmate PS

boards (60 cm. X 300 cm.) are placed on the beam rafters

in vertical direction to the beam rafters; and are

temporarily attached with nails.

- A

water-proof membrane with low vapour permeability

resistance (Sd£0.16m.) is

placed on top of each other from down below upwards.

- The Roofmate

PS boards as well as the pressure bars are fixed onto

the beam rafter with the help of head nails.

- For every

line of roof tiles one tile bar is aligned in the

vertical direction to the pressure bars and the roof

tiles are fixed to these bars.

- For the

application of Shingle water plywood, chip wood etc.

Type boards are placed on the pressure bars and this

shingle type cover is fixed onto these boards and the

roof is thus completed. In this application there is no

need for an extra water resistance membrane to be used.

- It is

advisable to keep the Roofmate PS boards and the bars to

be fixed at the same time and order and proceed with the

work. Application workers are advised not to walk around

these bars and the beam rafters.

1) Cushion,

2) Beam rafter,

3) Roofmate* PS thermal resistance board

4) Water proofing membrane

5) Tilling battens

6) Counter battens

7) Face wood

8) Roof cover (roof tiles, schingle) |

THE ADVANTAGES

- It doesn't

cause contusion; dissipation like other type of thermal

insulation materials placed onto the floor base of the

garret; is imputrescible against the effects of dust and

dampness and doesn't cause contusion and dissipation

like thermal insulation materials and does not lose its

value of thermal insulation level. It does not need

renewal every few years and keeps its thermal resistance

level for the life of the building itself.

- It does let

go high rates through the beam rafters and the beam

rafters act like a heat bridge like the thermal

resistant materials placed in-between the beam rafters.

- The area

under the roof, whether to be used as a living area or

not is made available for all purposes; hence an

additional dwelling to be used or to be sold is created

additionally.

- Is applied

at a faster pace than roof woods. Saves time and money

on workers time.

- The Roofmate

PS Boards carries a load of up to 150 kgs.in the area of

monopole and between the two beam rafters when size of

separation of the board rafters and board thickness are

applied as advised above (please refer to ODTÜ test

results).

- The bending

strength of the thermal insulation boards used for this

application must be 600 kPa for safety and the crushing

strength 40 tons/m2.

- It functions

as roof wood as well as thermal insulation material and

therefore the overall cost is lowr.

- Wood

consumption is at the lowest level. This way, protects

the forests.

TECHNICAL SPECIFICATIONS OF ROOFMATE PS FOR PITCHED ROOF

SOLUTIONS

MATERIALS WITH THERMAL RESISTANCE (TSE branded and

in conformity of TS 11989a). The cap less porous

Polystyrene - extruded foam XPS boards used for the beam

rafter pitched roofs without roof wood must definitely

have armed surfaces (TS 825 standards, official gazette

article number 10.2.1.2.2. of the attachment number 5,

dated June 14, 1999, numbered 23725). In the case of

some parts of the boards regarding the fixing of the

roof tiles for the application of pitched roofs placed

on the roof wood or the tilted roof cement being rough,

the water absorption ratios must not exceed % 0.5 in

volume with the use of full dipped method.

THERMAL CONDUCTIVITY (LAMDA). The rate at the end of

aging for 90 days at 10 C must not be larger than 0.027

W/m.K.

DENSITY: Density for the application must not be

lower than 36 kg/m3 on the beam rafter without roof

wood. Otherwise,it would not be possible to achieve a

pressure resistance of 400 kPa and bending resistance of

600 kPa.

PRESSURE RESISTANCE. It must not be lower than 400

kPa at the applications on the beam rafter without roof

wood (TS 11989, Class C4).

BENDING STRENGTH. It must not be lower than 600 kPa

at the applications on the beam rafter without roof

wood. Otherwise, people would not be able to walk on it.

Even at these values the thickness of the board and the

gaps left between beams rafters must not exceed the

values given by the manufacturers.

STRECH

RESISTANCE. It must not be lower than 140 kPa at the

applications on the beam rafter without roof wood. (This

value can be defined as the load at its maximum, which

the material can carry for 50 years on a continuous

basis under a deformation of up to 2 %. Also, as the

load for statistical calculations 140 kPa should be

taken as basis instead of 400 kPa).

WATER

ABSORBTION. The water absorption rate for prolonged

periods using full dipping method must not exceed 0.2 %

in volume.

WATER

ABSORBTION WITH DIFFUSION OVER LONG PERIODS. The

rate of water absorption with diffusion over long

periods must not exceed 1 % in volume.

FREEZE

THAW. The rate of water absorption using freeze thaw

method must not exceed 0.2 % in volume. Also, the

reduction in pressure resistance as the result of freeze

thaw test must not exceed 2 % (the rate of 10 % as the

standard is the upper limit).

WATER

VAPOUR DIFFUSION RESISTANCE. It must be between 100

and 200.

SIZE

DETERMINATION

a) Change of dimensions in the length and the width must

be zero at 60 C and 90 % relative humidity.

b) Change in dimensions must not exceed 2 % under 20-kPa

stresses and at a temperature of 80 C.

c) Must not exceed 2 % under 40-kPa stresses and at a

temperature of 70 C.

RESISTANCE TO FIRE. Must pass the B2 test first,

then must be proven that it has passed B1 class by

applying chimney furnace tests and that it has not been

dripping. Besides the documents obtained from TSE there

must also be certificates granted by the test institutes

in Germany.

CAPILARITY. Must be zero.

SPECIFICATIONS OF THE SURFACE. Must be armed

(binding).

LENGTH, WIDTH, DEVIATION FROM THE SET SQUARE, SURFACE

PLAIN, THICKNESS. Must be in conformity of TS 11989.

SIDE

PROFILES. Tongue grooved side profiles would prevent

the work of heat bridges.

|