|

WHERE ARE THEY USED?

They are used for the base floors, wooden flooring, and

systems with heating from the floor, the floors

separating the floors, in short for all the flooring

where heat loss can be anticipated.

HOW ARE THEY USED?

-

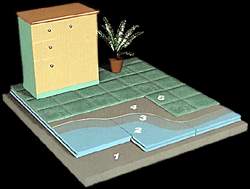

Directly onto the concrete floor and without

leaving any space or gap.

-

If a mortared floor lining is to be applied on

it, polyethylene layer is laid on top of it as a

separating layer and if required, a thin layer of alum

is spread and mortared lining is applied. For carpeted,

PVC wooden parquet linings etc. pasting or lathed

fixation is applied on the layer of alum.

-

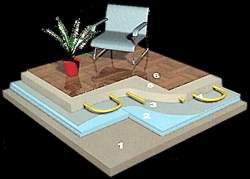

For the heated floors the boards are laid on top

of the floor concrete. After a polyethylene folio as

separating layer is laid, the heating pipes are placed

using plastic legs and an alum layer of appropriate

thickness is applied and care is taken so that the

heating pipes remain in the middle of the thickness of

the alum. After that the detail is completed with the

floor lining.

1) Floor

cement

2) Floormate* 200 thermal

insulation board

3) Separation layer,

poly-ethylene folio

4) Heating pipes

5) Alum

6) Floor covering materials

(parquet etc.)

|

|

1) Floor

cement

2) Floormate* 200 thermal

insulation board

3) Separation layer,

poly-ethylene folio

4) Mortar

5) Floor covering or alum

layer

|

|

ADVANTAGES

- Floormate* 200 possesses high

resistance qualities against pressure loads and

stretching over time. For that reason, it doesn't cause

wear out with the materials used for lining.

- Since the pressure resistance

is high it reduces cost for linings of the type similar

to mosaics.

- The water repent ionic quality

of the product enables protection of the specifications

relating to thermal resistance for possible incidents

and prevention of occurrence of damage likely to happen

over time especially for applications of structural

insulation, heating and cold storage houses.

TECHNICAL SPECIFICATIONS FOR

THE MATERIALS OF THE FLOORMATE 200 OFFICE AND

RESIDENTIAL BUILDING FLOORING INSULATION

MATERIALS FOR THERMAL RESISTANCE (TS 11989

compatible TSE standards). The cap less porous

polystyrene - extruded foam XPS boards used for the

flooring of offices and residential buildings must

definitely have armored (binded) surfaces (TSE 825

standards, article number 10.2.1.2.2. of attachment

number 5 of the official gazette numbered and dated

23725 and June 14, 1999).

RATE

OF THERMAL CONDUCTIVITY (LAMDA). It must not be

larger than 0.028 W/m.K after aging at 10 C for 90 days.

DENSITY. Must not be at lower than 30 kg/m3 density.

Under TS 825, article number 10.2.1.2.2 of attachment

number 5 the lower limit of density is clearly given as

30 kg/m3 for the boards with armored (binding) surfaces.

PRESSURE RESISTANCE. Must not be lower than 200 kPa

(TSE 11989, class C3).

STRECH

RESISTANCE. It must not be lower than 80 kPa. (This

value can be defined as the load at its maximum, which

the material can carry for 50 years on a continuous

basis under a deformation of up to 2 %. Also, as the

load for statically calculations 80 kPa should be taken

as basis instead of 200 kPa).

WATER

ABSORBTION. The water absorption rate for prolonged

periods using full dipping method must not exceed 0.2 %

in volume.

WATER

VAPOUR DIFFUSION RESISTANCE. It must be in between

100 and 200.

SIZE DETERMINATION

a) Change of dimensions in the length and the width must

be zero at 60 C and 90 % relative humidity.

b) Change in dimensions must not exceed 2 % under 20-kPa

stresses and at a temperature of 80 C.

c) Must not exceed 2 % under 40-kPa stresses and at a

temperature of 70 C.

RESISTANCE TO FIRE. Must pass the B2 test first,

then must be proven that it has passed B1 class by

applying furnace tests and that it has not been

dripping. Besides the documents obtained from TSE there

must also be certificates granted by the test institutes

in Germany.

CAPILARITY. Must be zero.

SPECIFICATIONS OF THE SURFACE. Must be armored

(binding).

LENGTH, WIDTH, DEVIATION FROM THE SET SQUARE, SURFACE

PLAIN, THICKNESS. Must be in conformity of the

tolerances under the TS 11989 standards.

SIDE

PROFILES. tongued side profiles would prevent the

work of heat bridges.

* Trademark of Dow

Chemical Company.

|